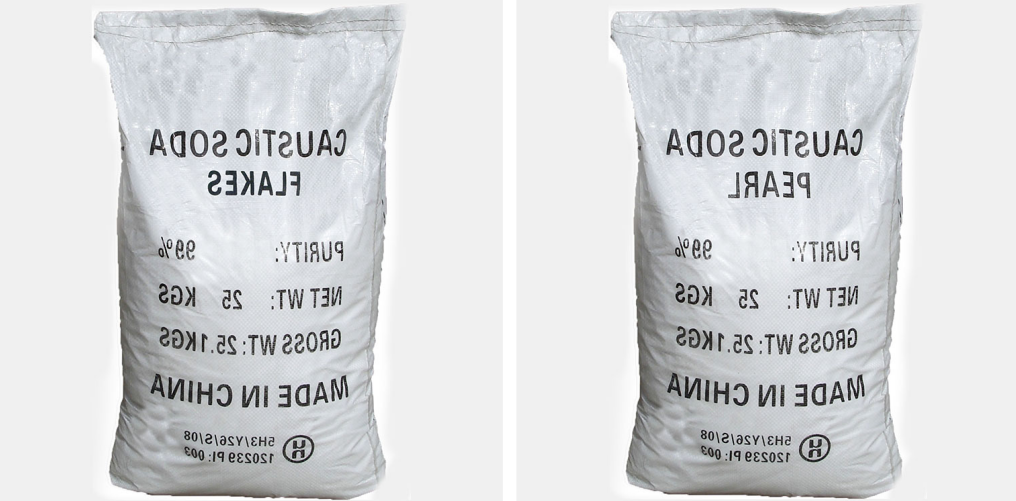

Caustic Soda Pearls &Flakes

SPECIFICATON

| Caustic soda | Flakes 96% | Flakes 99% | Solid 99% | Pearls 96% | Pearls 99% |

| NaOH | 96.68% Min | 99.28% Min | 99.30% Min | 96.60% Min | 99.35% Min |

| Na2COS | 1.2% Max | 0.5% Max | 0.5%Max | 1.5%Max | 0.5%Max |

| NaCl | 2.5% Max | 0.03% Max | 0.03% Max | 2.1% Max | 0.03% Max |

| Fe2O3 | 0.008 Max | 0.005 Max | 0.005% Max | 0.009% Max | 0.005% Max |

usage

Sodium hydroxide has many USES.Used for papermaking, soap, dye, rayon, aluminum, petroleum refining, cotton finishing, coal tarproduct purification, alkaline cleaning agent in water treatment and food processing, wood processing and machinery industry.The details are as follows:

Soap industry

used in water treatment as an oxygen scavenger agent.

used in pulp and paper industry.

used in pulp and paper industry.

used in textile industry as a bleaching, as a desulfurizing and as a dechlorinating agent.

1. The Versatility of Caustic Soda in Various Industries

1. Introduction

A. Definition and properties of caustic soda

B. The importance of caustic soda in the chemical industry

2. Application of caustic soda

A. Use as basic chemical raw materials

B. High-purity reagents for various industries

C. Widely used in chemical industry, metallurgy, papermaking, petroleum, textile, daily chemical and other industries

2. application

A. Soap manufacturing

B. Paper production

C.Synthetic fiber production

D. Cotton fabric finishing

E. Petroleum refining

3. Benefits of caustic soda

A. Versatility in different industrial processes

B. Important role in the production of various consumer goods

C. Contribution to the advancement of the chemical industry and manufacturing industry

4. Conclusion

A. Review of the importance of caustic soda in multiple industries

B. Emphasize its role as a basic chemical raw material

C. Encourage further exploration of its applications in various fields

The second largest consumer demand for caustic soda

It is mainly distributed in the printing and dyeing and chemical fiber industries, and the alkali consumption of finishing is currently stable. Printing and dyeing is the earliest major consumer of caustic soda. However, with the emphasis on environmental protection and industrial upgrading in recent years, the scale of the printing and dyeing industry has continued to shrink, and the alkali consumption has been reduced through technological innovation and other means.

In printing and dyeing, caustic soda is mainly used as a water softener to improve the coloring rate and uniformity of the printing and dyeing process. It is also used to remove impurities such as grease and small fibers. Generally speaking, the standard alkali consumption for printing and dyeing one hundred meters of fabric is 0.8-1.2 kg. The alkali consumption of chemical fiber mainly involves the production of viscose staple fibers. As a regenerated wood cellulose, the development of viscose staple fibers is also very rapid, and the demand for caustic soda is steadily increasing. In the chemical fiber industry, caustic soda is used to wash away impurities in wood fibers during the production of viscose staple fibers. It can also be used to refine and store cellulose and improve the appearance of fabrics. Generally speaking, 0.5 tons of caustic soda is required to produce one ton of viscose staple fibers.

The main purpose of using caustic soda in the pulp manufacturing process is to swell the fibers, which is conducive to the smooth pulping or liquid impregnation, saving energy, etc. Generally speaking, in pulping and papermaking, about 80 kilograms of caustic soda are consumed to produce one ton of product. At present, the annual consumption of caustic soda in pulping and papermaking is about 3 million tons.

packing

Packing is strong enough for long – time storage to against dampness , moisture. You required packing can be produced. 25kg bag.

loading

RAILWAY TRANSPORTATION

Company Certificate

Customer Vists